Our Story

Nimbus Suspensions is a family-owned company born from a shared passion for off-road adventure and precision engineering.

Created by Pierre-Olivier and his son Killian, Nimbus aims to bring the performance of oleo-pneumatic suspension systems to serious 4x4 enthusiasts.

With roots in Florida and a growing global presence, from Denver to Melbourne, the company remains grounded in its values of quality, craftsmanship, and community.

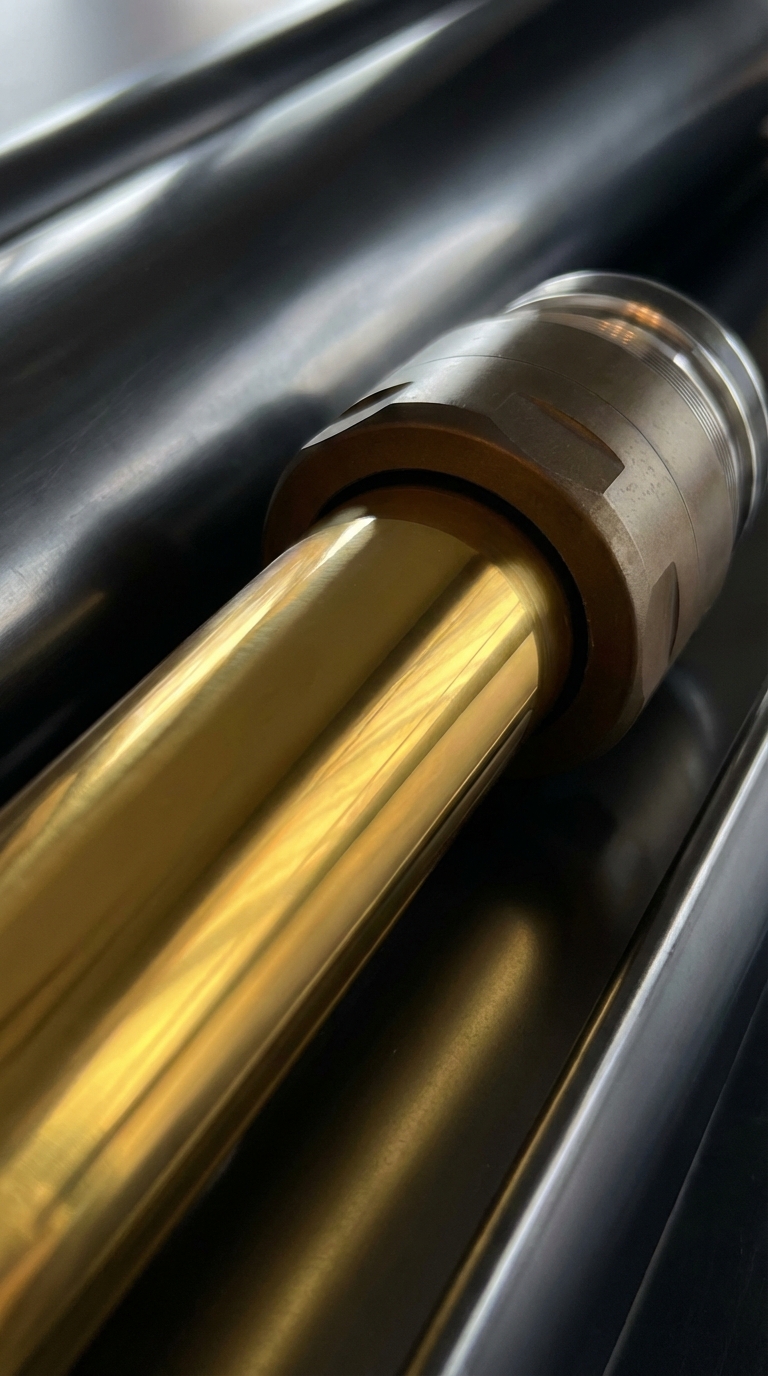

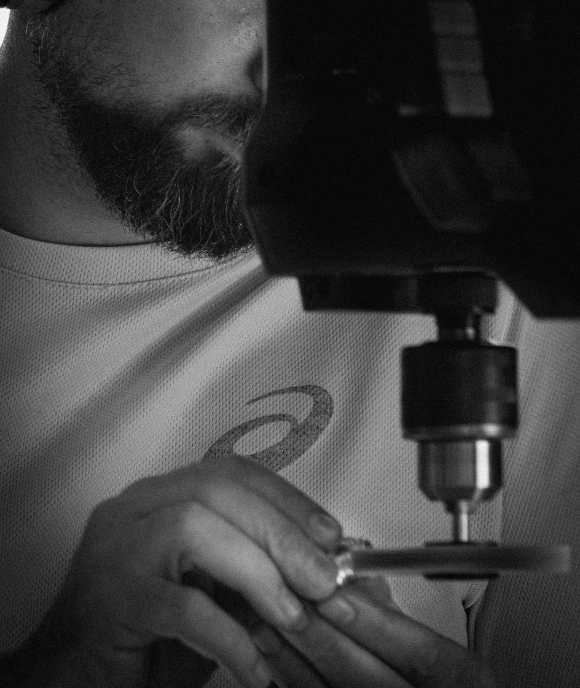

Every suspension is hand-built in our South of France facility, reflecting a deep commitment to excellence and a personal legacy shared with every customer.